I got my hands on a broken 3D scanner. I was happy to give it a try and see if I can return it to working condition. There’s some satisfaction in fixing things… 🙂 Alright, let’s see how that worked out!

The scanner

The unit has been developed by Matter and Form. It’s a small company located in Canada, offering currently 2 products (second one, Bevel, had a successful Kickstarter campaign in 2015).

You can learn more about the scanner here:

https://matterandform.net/scanner

If you’d like to purchase one, it’s available on Amazon:

The problem

The unit I got my hands on had an issue with the turntable. When attempting to do a scan, there would be grinding noise, and turntable wouldn’t rotate. Upon disassembly, I found out that there were 3 bearings missing at the bottom of the turntable – they provide support, and without them, there was a lot of movement in every direction preventing it from precise operation. I don’t know the prior history of this device, so I’m not exactly sure how that happened, but I suspect this would be caused by exercising a lot of force on the turntable (either by scanning very heavy object, or dropping something on it).

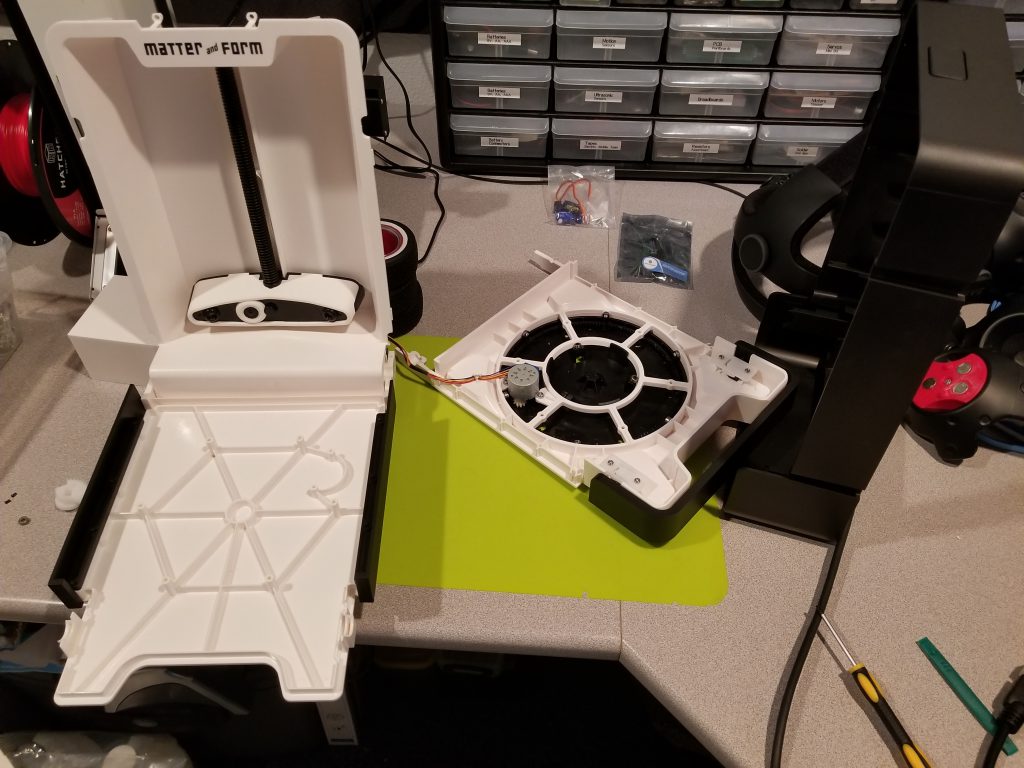

Unit with the turntable removed:

I reached out to the customer support at Matter and Form, described the issue, and was promptly offered the replacement part. That’s a great start!

The package arrived after about a week. Having waited for it, and being excited to finally give it a try, I proceeded with careful installation of the new turntable. The fitment is very tight, and there are 3 legs and 3 bearings that need to snap into the inside of the inner ring on the base.

Left – broken turntable, right – new one with bearings attached:

Well, the fitment is really very, very tight. That’s required for precise operation, but makes the assembly process quite tricky.

Unfortunately, during the installation, one of the bearings snapped off of the new turntable. I finished the installation with 2 out of 3 bearings in place, wondering if this will allow for a reliable operation. When testing, I came to conclusion that it’s unsatisfactory, not only did the turntable show a bit of skew at some angles while rotating because of the missing bearing, but it became clear that the wear and tear on the original base was getting in the way of smooth operation. The base must’ve gotten damaged at the time when the turntable got broken.

I contacted the support again, and was offered larger set of replacement parts (turntable along with the base assembly). I’d like to reiterate that again, the Matter and Form support is awesome. It’s not being outsourced, and instead you get to talk to people working directly for the company. They’re very knowledgeable, responsive and really helpful.

Another week has passed and I proceeded to unpack the second package.

The disassembly was more involving this time, but support provided very exhaustive instructions, which helped make sure that everything goes smoothly.

New replacement base on the left:

And original base removed:

The replacement came with turntable already installed on the base. This helps tremendously, as it eliminates the most risky part of the assembly process (which puts force on the bearings).

And the scanner all back in one piece:

So, did it work?

It did! Works like a brand new unit, operates very smoothly, and after a quick calibration provides a nice quality point clouds that can then be turned into meshes.

I began with a calibration, using provided test element:

And then it was time to start scanning.

Here’s an example piece that I chose because of the complex structure of the sides. It’s a pen holder that looks like stacked 3 car tires, with a detailed thread pattern. Seems like a good test to check the level of detail that can be achieved.

Scan in progress:

Completed scan, before cleaning up:

After the cleanup, while generating the mesh:

And the final result:

The resulting mesh was satisfactory. Note that we’re not only getting the mesh, but also textures. This is where even ambient light really helps.

This was just the first scan, I’m sure that with a bit of experimentation even better results can be achieved.

How would I rate this scanner?

Briefly – I like the idea of a compact device that can be folded and stored when not in use, the results are satisfactory, and I have to give a shout out to the great and responsive customer support. Downsides include construction made completely out of plastic (some parts feel flimsy, e.g. the power switch) and limitations of the current technology (long scanning times, precision).

Pros:

- Small form factor, foldable, doesn’t occupy much space,

- Great customer support,

- Simple to use software,

- Depending on the preparation (ambient light, etc.) has potential to provide nice results,

- Price not that far from reasonable range 🙂 ($499 at this time),

Cons:

- Noisy operation – the threaded rod for Z axis is made of plastic, and there seems to be some wiggle that contributes to the noise,

- A bit flimsy construction – the plastics are sometimes squeaky, power button requires a lot of force and resonates on press. The hinge where scanner opens and folds doesn’t have anything to lock it in position – I worry that this may affect the scanning precision. It’s a bit disappointing that pretty much whole device is made out of plastic. Compare that to the construction of Monoprice Select Mini, great 3D printer for just over $200 made almost completely out of metal. I understand the cost of various components is different between 3D printer and scanner, but I’d really like to see stronger construction, especially in the critical places that are so prone to failure right now (bearing mounts under the turntable).

- Very long scan times – that seems to be the limitation of current generation of 3D scanners. The number of scans, at different heights, from different angles, quickly creates a large set of measurements, and that takes time. Probably being able to make scans at multiple heights at once (multiple sensors at different height) would cut down the times significantly, but also increase the cost of the hardware.

- Quite pricey after all,

To learn more, visit https://matterandform.net/

I also recommend checking out the “DOs and DON’Ts“, as well as a tutorial video for setting up the scanner.

This concludes my first experience with a dedicated 3D scanner. There’s a still room for improvements, and this technology seems to be lagging behind 3D printing (I suspect that it’s mostly due to the popularity of 3D printing which thus receives more focus, as I wouldn’t think that scanning is facing greater technical challenges in comparison).

I know there are various DIY solutions built with the use of Kinnect, but I have yet to try those. Then there are few other products at a slightly higher price point that Matter and Form (like this one from MakerBot). And I’ve never really gotten great results with apps available for smartphones/tablets, that work by taking multiple photos at various angles and then processing them to create a mesh…

Do you have experience with hobby-grade 3D scanners? Let me know!

Leave a Reply